The Torsen (Torque-Sensing) limited-slip differential (LSD) is a purely mechanical device designed to combine the smooth operation of a conventional differential with the ability to direct torque to the wheel that can use it most effectively. Widely applied in performance, sports, and off-road vehicles, the Torsen LSD addresses the key problem that open differentials cannot solve: the loss of drive when one wheel slips. Understanding its operation requires looking at torque distribution, axial forces, and the mechanical design that allows it to sense torque differences.

Torque Bias Ratio

How Torque Is Distributed?

Axial Force and Friction

Preload and Differential Responsiveness

Conclusion

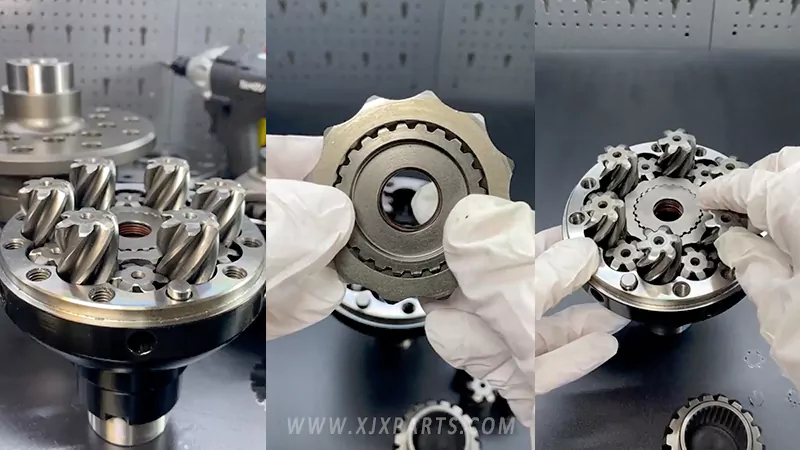

Looking for high-quality Torsen limited-slip differentials? XJXPARTS is a professional factory with over 20 years of experience in designing and manufacturing LSDs. We offer OEM and custom solutions to meet your specific vehicle requirements. Contact us today to discuss your project and get a tailored solution directly from the manufacturer.