For any automotive enthusiast, mechanic, or restorer working on a Ford project, few components are as critical—or as confusing—as the differential. Whether you are building a Fox-body Mustang for the drag strip, restoring a classic F-100, or simply replacing a worn-out gear set in your daily driver, knowing exactly what rear end is sitting under your chassis is the first step.

The “Ford 9-inch” may be legendary, but the reality of Ford’s production history is a complex web of varying axle models, gear ratios, and casing designs. Ordering the wrong ring and pinion set or the incorrect limited-slip carrier is a costly mistake.

This guide serves as your definitive resource for identifying Ford differentials. We will move beyond basic guessing and dive into visual cues, axle tag decoding, and the specific characteristics that define Ford’s most common rear ends.

Why Identification Matters Before You Buy

Before we dive into the “how-to,” it is important to understand why visual identification often trumps what the paperwork says. Ford vehicles, particularly older muscle cars and trucks, have often lived long lives. A Mustang that left the factory with an open 7.5-inch rear end in 1985 might have been swapped to an 8.8-inch posi-traction unit by a previous owner in the late 90s.

Relying solely on the VIN or the door sticker can be risky if the vehicle is not 100% original. Therefore, the most reliable method of identification combines decoding the factory tags (if present) with physical inspection of the housing shape, bolt patterns, and internal components.

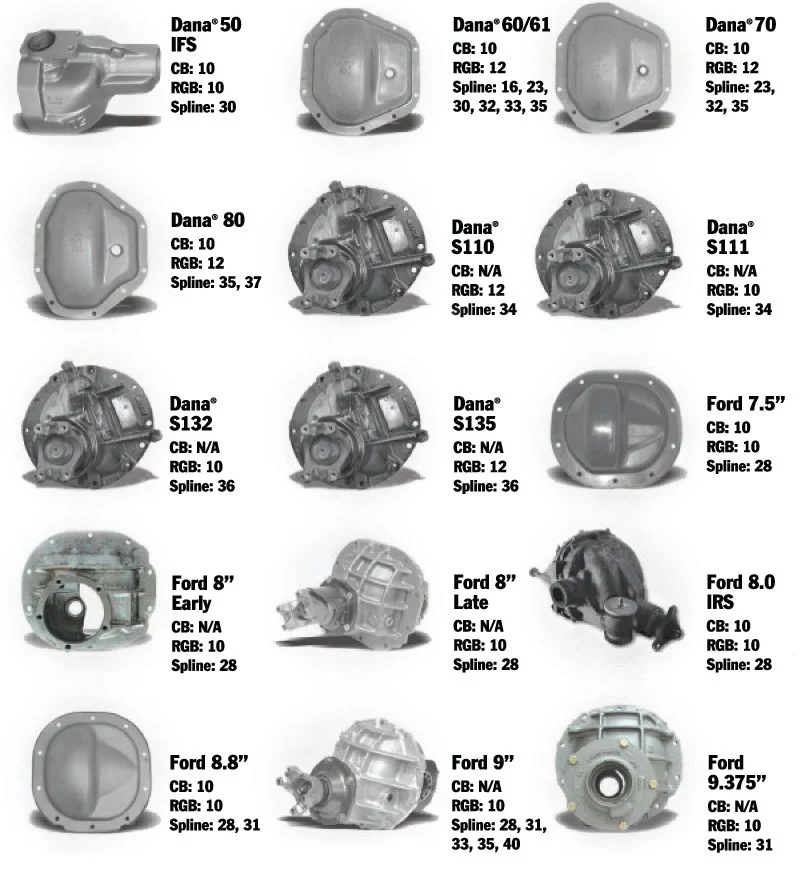

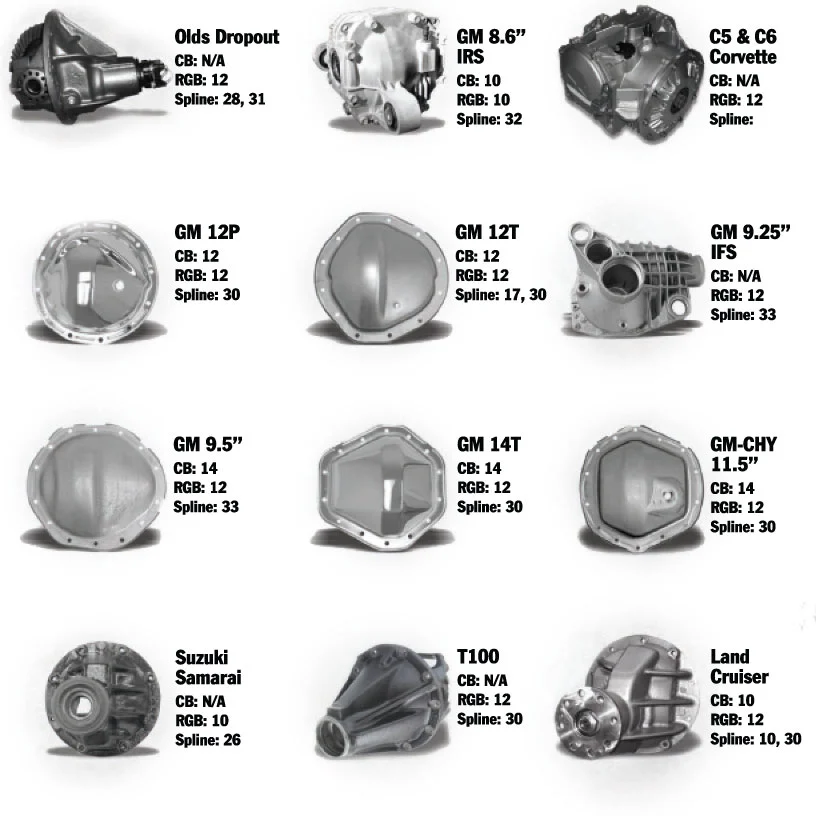

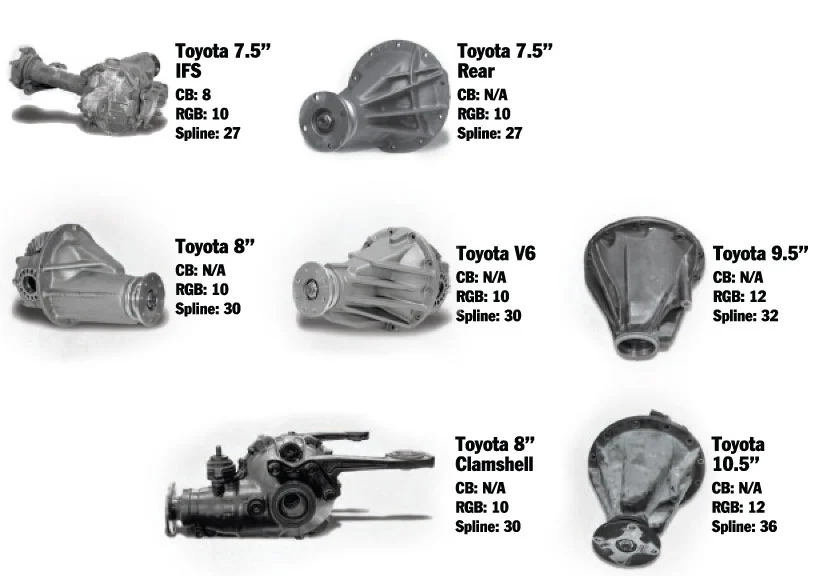

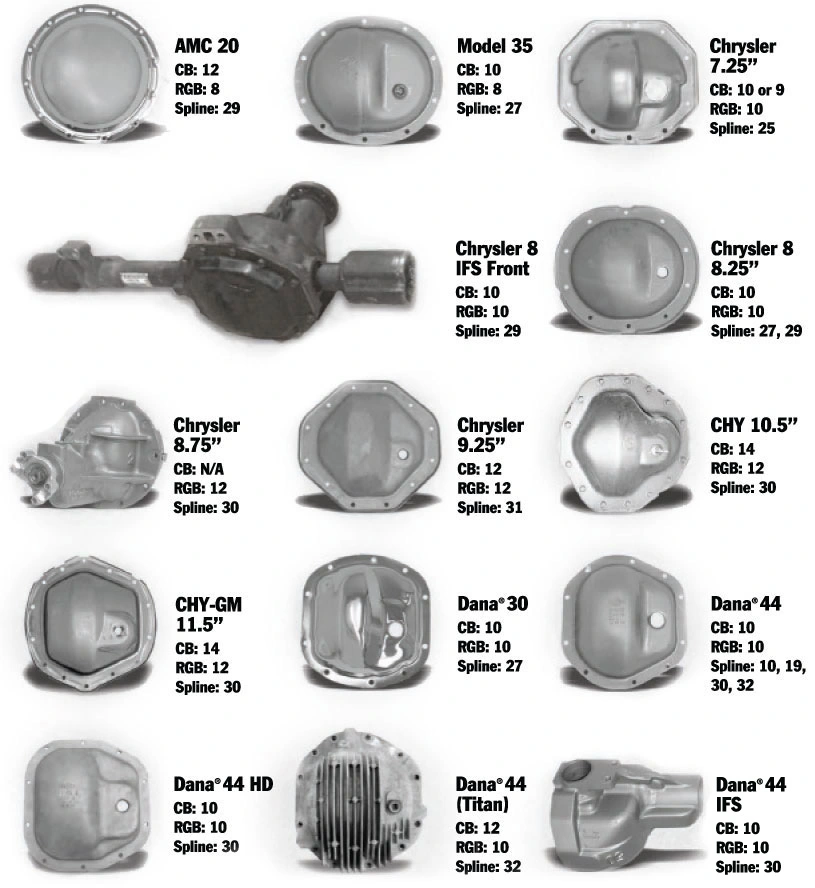

Method 1: Visual Identification by Cover and Bolt Count

If you are crawling under a truck or a car in a salvage yard, the quickest way to narrow down the differential type is by looking at the rear cover (or lack thereof) and counting the cover bolts. This “field identification” is the industry standard for a quick assessment.

The Removable Carrier Type (The "Drop-Out")

The most famous Ford axles utilize a “drop-out” third member. In these designs, there is no inspection cover on the back of the axle housing. The back is made of smooth steel, welded to the axle tubes. Instead, the entire center section (containing the gears and carrier) unbolts from the front of the housing.

- Ford 9-Inch: This is the holy grail of Ford axles. It is distinguishable by having no rear cover and a front center section held on by nuts. However, the key visual giveaway for a true 9-inch is that the bottom two nuts retain the carrier but cannot be accessed with a socket because the pinion support creates a visual obstruction. You generally need a wrench for the bottom two.

- Ford 8-Inch: Very similar to the 9-inch and often confused with it. The 8-inch was common in smaller muscle cars like the early Mustang, Falcon, and Fairlane. The easiest way to tell it apart from a 9-inch is the bolt access. On an 8-inch, you can access all the nuts holding the center section with a standard socket; the pinion support does not obstruct them.

The Integral Carrier Type (Salisbury Axle)

These axles have a removable inspection cover on the rear. To change gears, you must remove this cover and work inside the housing.

- Ford 8.8-Inch: The industry standard for modern Fords (Mustangs, Explorers, F-150s). It features a roughly square cover with rounded corners and 10 bolts. It looks remarkably similar to the GM 12-bolt cover but only has 10 bolts.

- Ford 7.5-Inch: Found in smaller vehicles like the Ranger, Bronco II, and V6 Mustangs. It also has 10 bolts, but the cover is smaller and more oval/flat on top compared to the square 8.8.

- Sterling 10.25 / 10.5: Found in heavy-duty trucks (F-250/F-350). These are massive axles with 12 bolts on the cover.

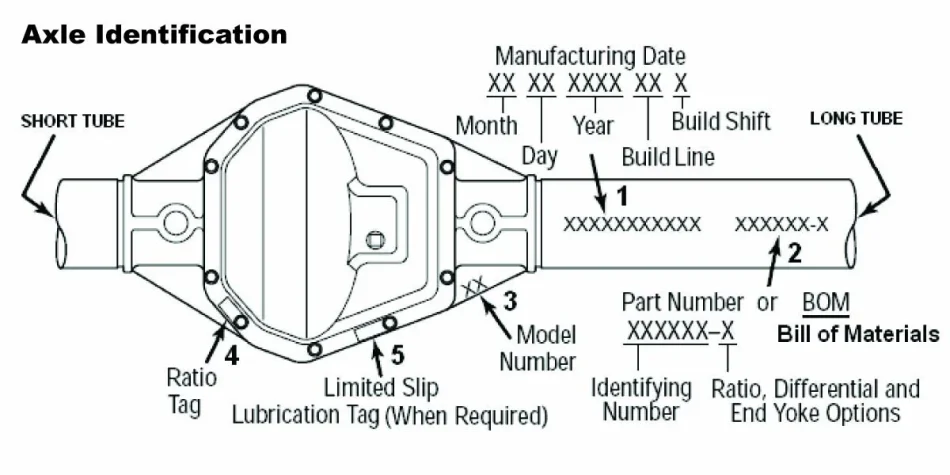

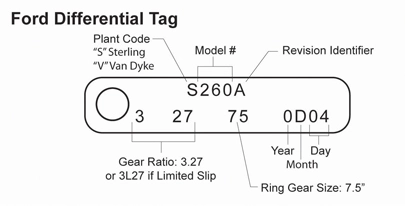

Method 2: Decoding the Metal Tag

If you are lucky, your differential still has the factory metal tag attached. This tag is usually secured by one of the diff cover bolts (on integral axles) or one of the carrier nuts (on drop-out axles). This tag is the Rosetta Stone of Ford differential identification.

The tag typically features two rows of alphanumeric codes.

Reading the Gear Ratio and Differential Type

Look at the bottom row of the tag. The first few numbers indicate the gear ratio and the limited-slip status.

- 3 55: This indicates a 3.55 gear ratio with an “Open” differential (non-locking).

- 3L55: The “L” inserted between the numbers indicates “Locking” (Limited Slip/Trac-Lok). This is a highly desirable find.

- 3 73: Indicates a 3.73 ratio, Open.

- 4L10: Indicates a 4.10 ratio, Locking.

Reading the Ring Gear Size

On the same bottom row, usually to the right of the ratio, you will see a number indicating the ring gear diameter.

- 88: Indicates an 8.8-inch ring gear.

- 9: Indicates a 9-inch ring gear.

- 75: Indicates a 7.5-inch ring gear.

Example Tag: Top Row: S838A (Plant and Model code) Bottom Row: 3L73 88 4K10

In this example, 3L73 88 tells us immediately that this is a 3.73 ratio, Limited Slip, 8.8-inch axle.

Method 3: The Door Jamb Safety Compliance Label

If the metal tag is missing (which is common on older vehicles due to rust or previous maintenance), you can look at the Safety Compliance Certification Label on the driver’s side door pillar.

Look for the box labeled AXLE. There will be a code, usually two characters (a letter and a number, or two numbers).

Common Ford Axle Codes (F-Series and Mustangs):

- 19: 3.55 Ratio, Non-Limited Slip

- H9: 3.55 Ratio, Limited Slip (Very common and desirable)

- 26: 3.73 Ratio, Non-Limited Slip

- B6: 3.73 Ratio, Limited Slip

- 27: 3.31 Ratio, Non-Limited Slip

- 45: 3.55 Ratio (Common in older trucks)

Note: Always remember that door codes only tell you what the car left the factory with. If the previous owner blew up the rear end and swapped it, the door sticker is invalid.

Deep Dive: The "Big Three" Ford Differentials

To ensure you are sourcing the correct internal parts, you need to understand the nuances of the most common differentials found in the Ford ecosystem.

1. The Ford 9-Inch

Produced roughly from 1957 to 1986, the 9-inch is iconic. Its strength lies in the placement of the pinion gear. The pinion engages the ring gear lower on the case (hypoid offset), which increases tooth contact and strength. Furthermore, it has an additional pinion support bearing at the nose of the pinion gear, preventing deflection under high torque.

Identification nuance: The 9-inch housing changes slightly over the years. The “Banjo” housing is the main shell. If you look at the back of the housing, early performance versions (1957-1960ish) might have a drain plug, while later ones do not. However, the two “dimples” on the back of the housing are a classic giveaway.

2. The Ford 8.8-Inch

Debuting in 1983, the 8.8 is arguably the most versatile axle Ford ever made. It is strong enough for almost any street application and is significantly lighter than the 9-inch.

Axle Spline Counts: This is where things get tricky with the 8.8.

- 28-Spline: Found in most standard Mustangs (Fox body and SN95 non-Cobras), Rangers, and Crown Victorias.

- 31-Spline: Significantly stronger. Found in F-150s, Explorers, and Mustang Cobras.

If you are hunting for an 8.8 in a junkyard for a swap, look for a 1995-2001 Ford Explorer. These almost exclusively came with 31-spline axles, 3.73 or 4.10 gears, and often had Trac-Lok. It is the best budget upgrade for a Jeep or an older muscle car.

3. The Ford 7.5-Inch

This differential is often physically interchangeable with the 8.8 in terms of mounting points on vehicles like the Mustang, but it is much weaker. It was standard on 4-cylinder and V6 Mustangs, as well as the Ford Ranger.

Warning: Do not confuse the 7.5 with the 8.8. They both have 10 cover bolts. The 7.5 cover is more oval, measuring roughly 10 7/8 inches wide by 9 3/4 inches high. The 8.8 cover is more square, measuring 10 7/8 inches wide by 11 inches high. If you plan on increasing horsepower, upgrading from a 7.5 to an 8.8 is virtually mandatory to prevent breakage.

Verification: Calculating Gear Ratio Without Tags

What if the tag is gone, the door has been replaced, and you have no idea what is inside the housing? You can determine the gear ratio mechanically. This method is foolproof.

- Safety First: Chock the front wheels and jack up the rear of the vehicle. Place it securely on jack stands. Put the transmission in neutral.

- The Marking: Use a piece of chalk or masking tape to make a mark on the driveshaft (lengthwise) and a corresponding mark on the inside of the rear tire.

- The Rotation:

- If you have a Limited Slip (both wheels spin the same way): Rotate the tire exactly one full turn while counting how many times the driveshaft spins.

- If you have an Open Diff (wheels spin opposite): You may need to hold one wheel still (or let it stay on the ground) and rotate the free tire two full turns to get the accurate driveshaft count.

- The Result:

- If the driveshaft spins just over 3 times, you likely have 3.08 gears.

- If it spins 3 and a half times, you have 3.55s.

- If it spins almost 3 and three-quarters times, you have 3.73s.

- If it spins just over 4 times, you have 4.10s.

Common Issues and Replacement Parts

Once you have identified your differential, you may encounter common wear items. Ford differentials are generally robust, but high mileage takes its toll.

- Trac-Lok Clutch Wear: The Ford Trac-Lok uses friction clutches. Over time (usually 70,000-100,000 miles), these wear out, and the differential begins to behave like an open diff (one-wheel peel). If you identify an “L” on your tag, but both wheels do not lock up during a burnout or in mud, your clutch pack needs rebuilding.

- Pinion Seal Leaks: A wet spot at the front of the differential where the driveshaft connects indicates a failing pinion seal.

- Carrier Bearing Noise: A whining or growling noise that increases with speed usually points to worn carrier bearings or ring and pinion misalignment.

Sourcing the Right Components

Identifying your Ford differential is only the first step in the repair or restoration process. The precision required to manufacture differential gears, axle shafts, and internal components is immense. A slight deviation in the contact pattern of a ring and pinion gear set can lead to noisy operation and catastrophic failure within miles.

When looking for replacement parts—whether it is a simple seal kit, a robust 31-spline axle shaft, or a complete ring and pinion gear set—it is crucial to source from manufacturers who understand the metallurgy and engineering tolerances of these specific axle families.

About XinJin Auto Parts

At XJXPARTS, we specialize in the manufacturing of high-quality automotive components. As a dedicated factory, we control the production process to ensure that our parts meet or exceed OEM specifications. We understand the intricacies of differential systems and provide precision-engineered solutions for your automotive needs.

If you are a distributor, a repair shop, or a business looking for reliable drivetrain components, we are here to help. To discuss your requirements and see how our factory can support your business with premium parts.