If you have ever pushed a car hard through a corner or launched aggressively from a standstill, you are likely familiar with the “one-tire fire.” It is that frustrating moment when all your engine’s power evaporates into a cloud of smoke from a single spinning wheel, while the other wheel sits motionless, providing zero forward momentum. This is the inherent weakness of the standard open differential found in most commuter vehicles.

For the driving enthusiast, the solution is not just more power; it is better traction. This is where Limited Slip Differentials (LSD) come into play.

The Problem with Open Differentials

To understand why you need an LSD, you must first understand the problem it solves. An open differential is designed for one primary purpose: to allow the outside wheel to rotate faster than the inside wheel during a turn. Without this capability, your tires would scrub and drag across the pavement every time you navigated a parking lot.

However, open differentials follow the path of least resistance. If one wheel loses traction—whether due to ice, loose gravel, or extreme cornering force—the differential sends almost all the power to that slipping wheel. The result is a total loss of acceleration. A Limited Slip Differential solves this by limiting the speed difference between the two wheels, ensuring that torque is distributed to the wheel that actually has grip.

Helical Gear Limited Slip Differentials

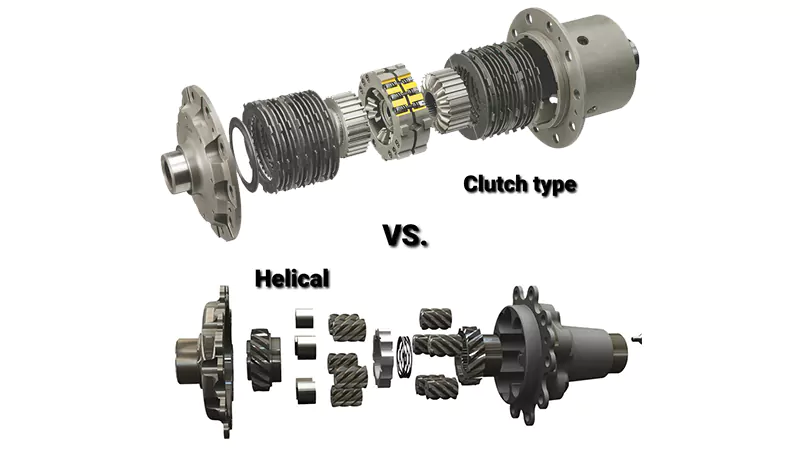

The Helical LSD, often referred to as a Torque Biasing differential or a geared LSD (such as the famous Quaife ATB or Torsen style), relies on a complex arrangement of internal worm gears. Unlike the stock differential, which uses simple spider gears, a helical system uses the friction generated between the gear teeth and the casing to redistribute torque.

How It Works

The magic of the helical gear LSD lies in its continuous, progressive operation. It does not “lock” in a binary on-off fashion. Instead, it mechanically senses which wheel is losing torque and instantly biases power to the wheel with more grip. The bias ratio (often around 3:1 or 4:1) determines how much torque can be transferred.

The Advantages of Helical Gears

For many drivers, the helical gear setup is the gold standard for mixed-use vehicles.

- Fit and Forget Reliability: Since there are no clutches to wear out, a helical differential generally requires no maintenance other than standard oil changes. It retains its performance characteristics for the life of the car.

- Smooth Engagement: No clunking or jerking. The torque transfer is so seamless that the driver rarely feels the differential working; they simply notice that the car has significantly more grip exiting corners.

- FWD Friendliness: For front-wheel-drive vehicles, helical differentials are often preferred because they reduce torque steer and do not fight the steering wheel during low-speed maneuvers like parking.

When it comes to manufacturing these precision units, expertise is key. XJXPARTS specializes in the production of high-quality Torsen-style helical gear LSDs, ensuring optimal performance and lifetime reliability for your vehicle. If you require a robust, maintenance-free solution for enhanced traction, please feel free to contact us to discuss your specific needs.

The Limitations

The Achilles’ heel of the helical gear LSD appears in extreme environments. Because the system relies on multiplying the resistance of the slipping wheel, it requires some load on both wheels to function. If you lift a wheel completely off the ground—common in aggressive curbing on a race track or extreme off-roading—the helical diff will act like an open diff, and the lifted wheel will spin freely.

Plate Type Limited Slip Differentials: The Motorsport Standard

On the other side of the Helical Gear vs Plate Diffs equation lies the Plate LSD (also known as a Clutch Type or Saloon style). This technology dominates professional drifting, rallying, and serious circuit racing.

How It Works

A plate differential operates similarly to the clutch in your transmission. It contains a series of friction plates and steel plates housed within the differential carrier. Pressure rings with angled ramps press these plates together when torque is applied. The friction between the plates locks the two axle shafts together, forcing them to turn at the same speed regardless of traction conditions.

The Advantages of Plate Diffs

- Total Locking Capability: Unlike the helical gear, a plate diff does not care if one wheel is in the air. It mechanically locks the axles. If one wheel is off the ground, the other wheel will still receive 50% of the power to drive the car forward.

- Tunability: This is crucial for race teams. By changing the ramp angles and the stacking order of the clutch plates, you can adjust exactly when and how aggressively the differential locks.

- Predictability for Drifting: For drift cars, a plate LSD is essential. It ensures that both rear wheels spin at the exact same speed, making it much easier to initiate and maintain a controlled slide.

The Limitations

Performance comes at a price. Plate differentials are “wear items.” Over time, the clutch plates will wear down and require replacement or “shimming” to maintain their locking ability. Furthermore, they can be harsh on the street. Low-speed turns can result in chatter, tire hopping, and clunking noises as the plates fight against the natural speed difference of the wheels.

Understanding Ramp Angles: 1-Way, 1.5-Way, and 2-Way

- 1-Way LSD: This differential only locks under acceleration. When you lift off the throttle, it unlocks completely and behaves like an open differential. This is ideal for FWD track cars or street cars where turn-in stability is required.

- 1.5-Way LSD: The most popular choice for all-around performance. It locks fully under acceleration and provides a milder, partial lock under deceleration (braking). This adds stability when braking into a corner without inducing excessive understeer.

- 2-Way LSD: This unit locks equally hard under both acceleration and deceleration. This is the preferred setup for drift cars, as it keeps the rear end stable and locked even when the driver is off the throttle mid-transition.

Helical Gear vs Plate Diffs: Which Application Suits You?

Choosing between these two technologies requires an honest assessment of how you use your vehicle. It is not about which technology is “newer” or “better” on paper, but which one aligns with your driving environment.

The Street & Track Day Warrior

If your car serves as a daily driver that sees occasional canyon runs or weekend track days, the Helical Gear LSD is almost always the superior choice. The refinement is unmatched. You will not have to deal with the clunky noises in parking garages or the accelerated tire wear associated with locked axles. The maintenance-free nature of the gears means you install it once and enjoy the benefits of enhanced traction for years without worrying about rebuild intervals.

The Dedicated Track, Rally, or Drift Car

If lap times, drift angles, or loose surfaces (gravel/snow) are your priority, the Plate Diff is the correct tool. In rallying, where wheels are constantly leaving the ground, a helical gear setup would result in a loss of drive. In drifting, the consistency of a locked rear end is non-negotiable. While the maintenance is higher, the performance ceiling is higher for these specific disciplines.

Maintenance Considerations

- Lubrication: Plate differentials often require specialized oils with friction modifiers to reduce plate chatter. Using the wrong oil can ruin the plates or make the driving experience unbearable. Helical gears generally run on standard high-quality gear oil.

- Heat: Plate differentials generate more heat due to friction. If you are racing a plate diff, you may need to invest in a differential cooler or a high-capacity cover to prevent fluid overheating.

Optimization and Handling Dynamics

Conclusion: Making the Final Decision

High-Quality Drivetrain Components from the Source

If you have questions about which differential is right for your specific application, or if you are looking for direct-from-factory manufacturing, we are here to help.