Simply put, the purpose of a open differential is to allow the left and right wheels on the same axle to rotate at different speeds during cornering, eliminating wheel “pull,” tire noise, and smoother cornering.

However, in extreme scenarios, such as when one wheel is suspended in mid-air and the other is stuck in a mud pit, a conventional open differential will cause power to flow to the side with the least resistance—the spinning wheel—resulting in a “spin” with no traction.

Once a lockable differential is locked, it forces both wheels to rotate at the same speed. Regardless of which side is gripping or spinning, as long as one side has grip, power can be transferred. Because of this, “differential lock” is a must or additional option in off-road, heavy-load, traction, agricultural, forestry, and engineering vehicles.

When one wheel gets stuck in mud, sand, snow, or becomes suspended in the air, a conventional differential wastes power on the wheel that loses traction. When a lockable differential is locked, the remaining wheel with traction also receives power, helping the vehicle continue forward.

For users who frequently drive off-road, up and down hills, or traverse unpaved roads, this “locking” function can significantly improve escape ability.

Under certain load or traction conditions (such as towing, heavy loads, or large wheels and tires), one wheel may have better traction than the other. In these cases, an open differential will deactivate the wheel with better traction. A lockable differential balances the power output between the left and right wheels, providing greater propulsion and controllability.

Note: Not a perfect solution for everyday driving.

While lockable differentials offer significant advantages, locking the wheels on normal paved roads and in high-grip conditions can have some negative consequences:

When cornering, the inside and outside wheels should rotate at different speeds. Locking them can cause tire noise and increase wear on the tires and drivetrain.

Locking the differential on the front axle can make steering heavy and the vehicle more difficult to control. Improper use can damage components such as the transmission, driveshaft, and differential. Therefore, knowing when to lock and unlock a lockable differential is crucial.

We can understand this by looking at the transition from a “open differential” to a “locking differential.”

When both wheels have equal traction, the left and right wheels rotate at different speeds, but output the same torque. When cornering, the inside wheel rotates slower and the outside wheel rotates faster, and the differential works normally.

However, if one side completely loses traction (for example, when in air or on icy surfaces), an open differential will transfer power to the side with the lowest resistance, effectively preventing the car from moving.

When a lockable differential is “locked,” the two wheels are forced to rotate at the same speed, regardless of traction conditions. This way, whichever side has traction takes over propulsion.

Locking differentials can lock the axles together to provide 100% of available torque to the wheel with traction.

Lockable differentials can be broadly divided into the following categories:

Automatically locks/unlocks the differential when a loss of grip is detected or a certain torque differential is reached. Advantage: No driver input required. Disadvantage: May exhibit erratic behavior during everyday driving (e.g., sudden locking/unlocking while cornering, causing jerkiness or tire squeal).

The driver selects whether to lock the differential using a button, lever, or electronic control. Examples include pneumatic locks, electronic locks, and electromagnetic locks. Advantage: Greater flexibility, allowing locking only when needed. Disadvantage: More complex construction and higher cost.

The differential is effectively locked internally or replaced with a solid piece connecting the axle ends. Advantage: Maximum grip, but extremely unfriendly for daily paved road use.

Many drivers ask: “I have a lockable differential, so what’s the difference between it and a limited-slip differential (LSD)?” Actually, there’s a significant difference.

When one wheel completely loses grip (either in the air or on an extremely slippery surface), the LSD’s performance is limited and may still result in power loss. It offers better and smoother performance in everyday paved driving (including cornering and high-speed driving).

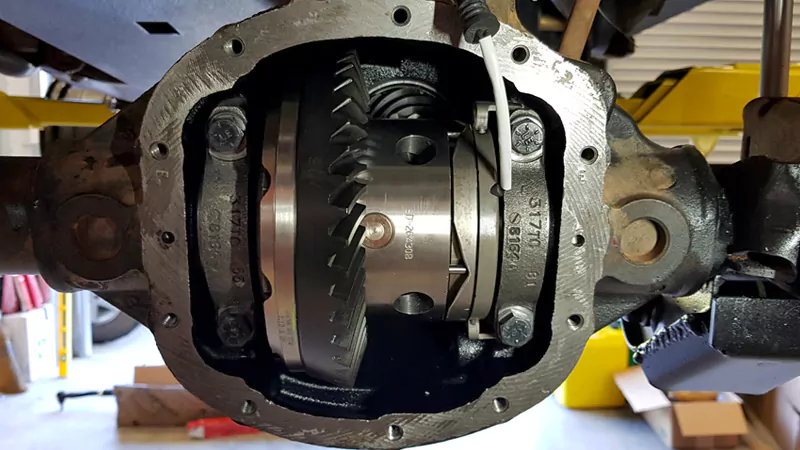

Lockable differential: Incorporating friction plates, gears, and spring elements into the differential structure allows the left and right wheels to direct some power to the side with better grip when there’s a difference in grip.

But there’s also the issue of “too much is as bad as too little”: using it incorrectly in normal, everyday driving conditions can lead to unnecessary strain. If your primary use is paved roads, high-speed driving, and occasional light off-roading, then an LSD is more suitable. If you’re an off-road enthusiast, towing heavy loads, and frequent use on unpaved roads, then a lockable differential is more appropriate.

If you’re planning to add (or upgrade) a locking differential to your vehicle, the following aspects are worth considering in advance.

Different vehicle models and axle specifications vary. When selecting a locking differential, it’s crucial to match the original vehicle’s differential, bearings, gear ratio, tire size, and trailer/load requirements. Improper installation can shorten lifespan and increase malfunctions.

Automatic vs. Manual/Electronic Control: Automatic locking is convenient but may exhibit erratic behavior in everyday driving; manual control requires driver intervention but offers agile control.

Operating Mechanisms: Pneumatic, vacuum, electromagnetic, mechanical lever/switch. Operating complexity and modification costs vary.

Ideally, the differential should be in the “unlocked” or “open” position for paved roads/normal driving, and switched to the “locked” position for extreme towing or off-roading. This ensures comfortable everyday driving while also providing strong traction when locked. If a locking differential only locks but doesn’t unlock, or if unlocking is difficult, it reduces daily usability.

Choose a well-known brand, a reliable supplier, a product that’s compatible with your vehicle, and guarantees excellent after-sales service.