When you’re crawling over rocky inclines, wading through deep mud, or navigating steep sand dunes, every second of traction matters. One moment too late, and your rig could get stuck—or worse, tip over. This is where air lockers prove their worth. Unlike mechanical or clutch-type differentials, which rely on wheel rotation or gradual torque transfer, air lockers engage instantly, giving both wheels on an axle full traction at a flip of a switch.

How Air Lockers Work?

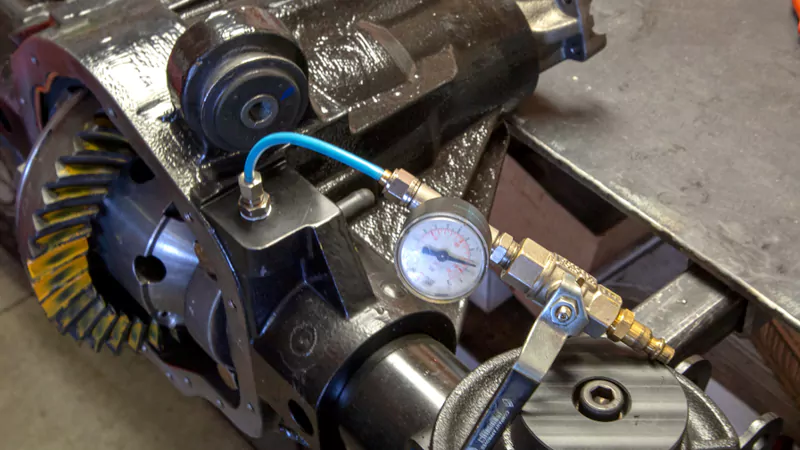

- Air compressor: Provides the necessary pressure

- Air lines: Deliver compressed air to the differential

- Control valves and switches: Allow the driver to engage or disengage the locker on demand

Advantages of Air Lockers

1. Immediate Traction

2. Superior Performance in Extreme Conditions

3. Enhanced Vehicle Control and Safety

4. On-Demand Flexibility

Disadvantages of Air Lockers

1. System Complexity

2. Additional Cost

4. Limited On-Road Use

Conclusion

XJXPARTS, as a manufacturer of high-quality limited-slip differentials and e-locker, air lockers, we specialize in designing and producing reliable traction solutions for extreme off-road conditions. Contact us today to explore our range of products and upgrade your vehicle’s drivetrain for maximum performance and safety.