When a vehicle turns, the outer wheels travel a wider arc than the inner wheels. This difference in turning radius results in a difference in turning speed between the inner and outer wheels. While the front wheels can spin independently and turn at different speeds, the rear wheels are connected to the engine through the gearbox and tailshaft. The differential’s role is to transfer power from the engine to the rear wheels (or front wheels in a front-wheel-drive car) while allowing them to spin at different rates. This variation in rotation speed is what the term “differential” refers to.

The most basic type of differential is known as an open differential. It allows the wheels to spin independently, which is suitable for everyday driving conditions.

However, a performance problem arises when there is not enough traction to transfer power from the tire to the road. This situation can occur on wet or slippery road surfaces or when the engine is highly powered. In such scenarios, the wheel with the least traction receives all the power, while the other wheel, which may have more traction, spins freely. This phenomenon is known as “single spinning.”

Mechanical LSD Differentials

To address this issue, mechanical LSD differentials are used. These differentials use mechanical components, such as clutch plates or friction discs, to control torque distribution between the wheels. When one wheel loses traction, the LSD engages to limit wheel slip and ensure that power is transferred to the wheel with traction. This improves traction and stability, especially in challenging driving conditions.

Mechanical LSD differentials play a crucial role in enhancing a vehicle’s traction and stability. They achieve this by controlling torque distribution between the wheels, ensuring optimal power delivery in various driving conditions.

It is worth noting that, Clutch-type limited-slip differentials belong to the category of mechanical LSDs, but mechanical LSDs encompass more than just friction plate-type differentials. Mechanical LSDs include various types, each with its own unique design and functionality.

- Torsen/Helical LSD

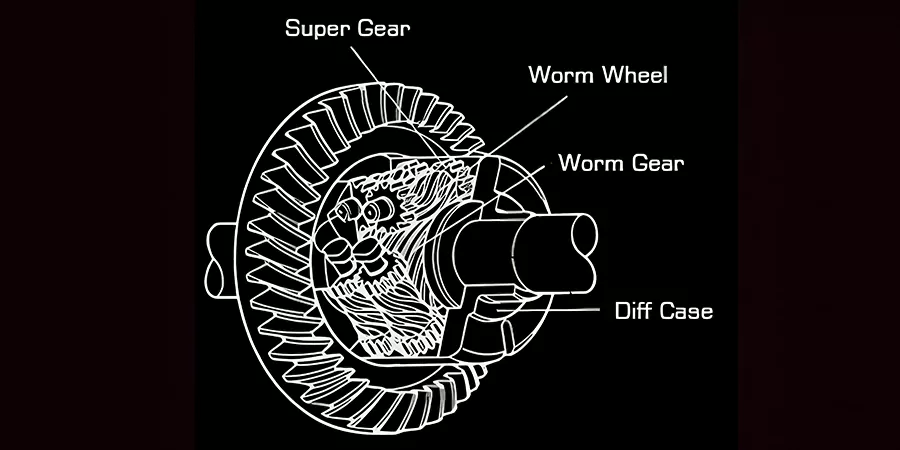

Torsen (Torque Sensing) or helical LSDs use a set of helical gears to transfer torque between the wheels. They do not rely on clutch plates, making them more durable and less prone to wear. Torsen LSDs are known for their ability to automatically adjust torque distribution based on wheel slip, providing excellent traction and stability in various driving conditions.

- Friction Plate-Type LSD

Friction plate-type LSDs, also known as clutch-type LSDs, use clutch plates to control torque distribution between the wheels. When one wheel loses traction, the clutch plates engage to limit wheel slip and ensure power is transferred to the wheel with traction. This type of LSD is common in performance and racing vehicles due to its effectiveness in providing traction and stability.

- Cone-Type LSD

Cone-type LSDs use conical friction surfaces to control torque transfer. They are known for their smooth and progressive engagement, making them suitable for both performance driving and daily use. Cone-type LSDs are often favored for their predictable and consistent behavior.

Conclusion

In summary, mechanical LSD differentials are essential for improving a vehicle’s traction and stability, especially in challenging driving conditions. They achieve this by controlling torque distribution between the wheels, ensuring optimal power delivery. With various types available, such as clutch-type, Torsen, and cone-type LSDs, drivers can choose the LSD that best suits their driving needs and vehicle requirements.